Installing Garlic Processing Production Line in Bangladesh: Technology Empowers Industry, Cooperation Writes a New Chapter

Installing Garlic Processing Production Line in Bangladesh: Technology Empowers Industry, Cooperation Writes a New Chapter

To ensure the smooth installation and commissioning of the garlic processing production line in Bangladesh, we have assembled a professional installation team with rich experience, who have traveled thousands of miles to the project site there to carry out their work.

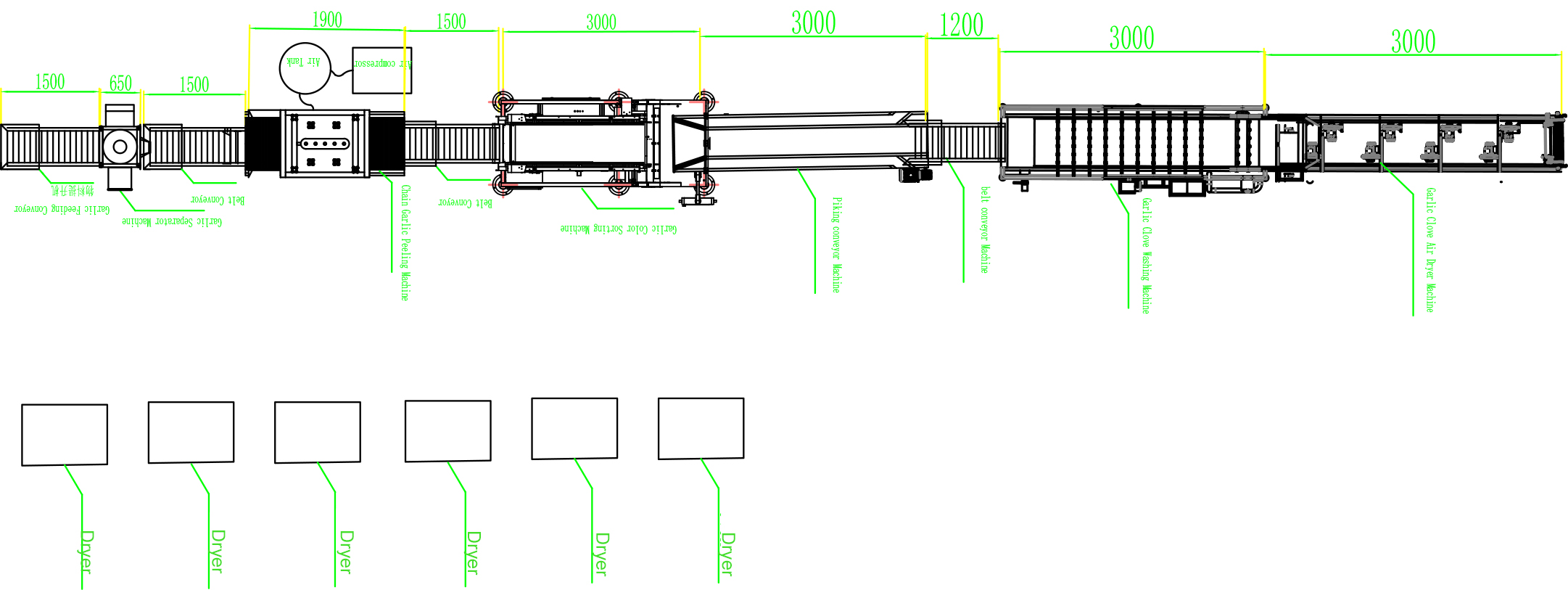

This production line integrates advanced technologies and craftsmanship, boasting multiple core functions: it can accurately sort garlic by size and quality; the automated peeling system greatly improves peeling efficiency while reducing manual losses; the fine processing 环节 can produce garlic clove products that meet various market standards. Moreover, it is equipped with an intelligent control system, featuring simple and stable operation, which enables continuous production and significantly enhances production efficiency.

During the on-site installation, team members braved high temperatures and harsh conditions to meticulously complete tasks such as equipment installation, circuit connection, and overall debugging, ensuring that all equipment operates at its optimal performance.

This project is of great significance. It not only helps Bangladesh improve its garlic industry chain, increase the added value of agricultural products, and drive employment and economic development, but also creates opportunities for us to expand the international market and enhance brand influence, promoting international exchanges and integration in the agricultural industry. Currently, the installation work is progressing steadily, and we look forward to the early commissioning of the production line, which will inject vitality into the local industry and write a new chapter in international cooperation.

mașină alimentară

mașină alimentară